Lean Management Training by Swades QMS

Welcome to Swades QMS’s comprehensive Lean Management Training program, a transformative solution aimed at empowering businesses of all sizes to excel in today’s dynamic marketplace. Our expertly crafted training equips you with the essential tools and methodologies to streamline operations, eliminate inefficiencies, and foster a culture of continuous improvement. As a trusted leader in Lean Management education, Swades QMS stands at the forefront of enabling organizations to achieve operational excellence and sustainable growth.

Course Offerings

Foundation of Lean Principles:

- Introduction to Lean concepts and their significance in modern business.

- Understanding the 5 principles of Lean: Value, Value Stream, Flow, Pull, and Perfection.

Lean Tools and Techniques:

- In-depth exploration of essential Lean tools such as Kaizen, 5S, Kanban, and Value Stream Mapping.

- Practical application of tools to eliminate waste, improves processes, and enhances quality.

Leadership in Lean Environments:

- Developing leadership skills that foster a culture of continuous improvement.

- Strategies for effective team collaboration, communication, and problem-solving.

Implementing Lean in Your Organization:

- Step-by-step guidance on implementing Lean principles in various business functions.

- Real-world case studies showcasing successful Lean transformations.

Sustaining Lean Practices:

- Strategies to maintain and sustain Lean initiatives for long-term success.

- Monitoring, measuring, and adapting Lean processes as your business evolves.

Who Can Benefit:

- Business Owners and Entrepreneurs

- Operations and Production Managers

- Supply Chain and Logistics Professionals

- Quality Control and Process Improvement Teams

- Project Managers and Team Leads

Our Lean Management Training Approach

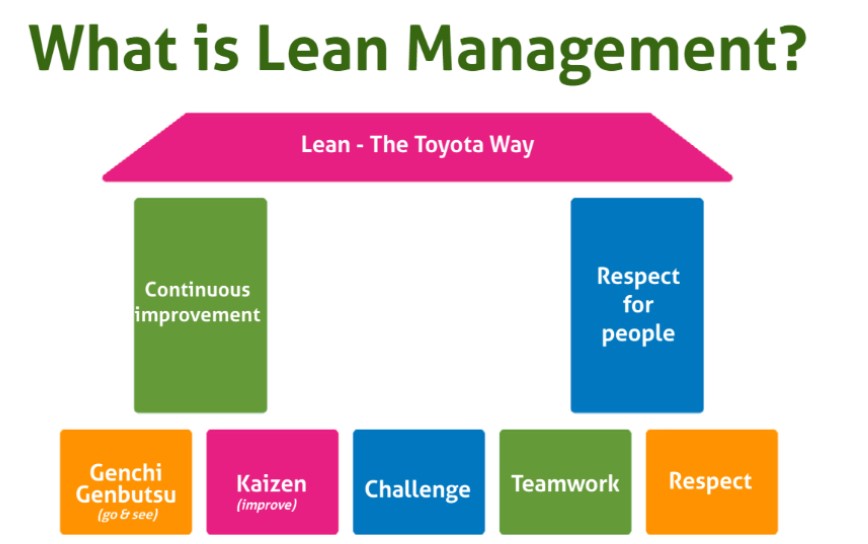

- Fundamentals of Lean: Understanding the core principles and concepts of Lean Management.

- Value Stream Mapping: Identifying value-added processes and eliminating non-value-added activities.

- Waste Reduction Strategies: Learning how to identify and minimize various forms of waste.

- Continuous Improvement: Establishing a culture of ongoing enhancements for sustained results.

Key Benefits of Lean Management Training

- Improved Efficiency: Streamlining processes leads to reduced lead times and increased throughput.

- Cost Savings: Eliminating waste directly impacts the bottom line, enhancing profitability.

- Enhanced Quality: Focus on quality at every stage for better customer satisfaction.

- Employee Empowerment: Involving employees in improvement initiatives boosts morale and engagement.

Why Choose Swades QMS for Your Lean Management Training Needs?

- Industry-Leading Expertise: Harness the wealth of knowledge accumulated through years of successfully implementing Lean Management solutions across diverse industries, including manufacturing, healthcare, and services.

- Customized Training: Our programs are tailored to meet the specific challenges and goals of your business, ensuring a highly relevant and impactful learning experience.

- Hands-On Learning: Dive into practical, real-world scenarios and case studies that enable you to confidently apply Lean principles to your organization’s unique context.

Embark on a transformational journey with Swades QMS’s distinguished Lean Management Training program. Empower your organization to flourish in today’s competitive landscape by harnessing the power of Lean principles. Our commitment to operational excellence and sustainable growth positions you for success. Reach out to us today and take the first step towards realizing your business’s full potential!