MSA – Measurement System Analysis Training

Measurement System Analysis (MSA) is a key factor in ensuring accurate and reliable measurement systems for any organization. By assessing and improving measurement system performance, MSA helps organizations make informed decisions based on reliable data, leading to improved quality control and customer satisfaction. At Swades QMS, we offer the MSA – Measurement System Analysis Training, which equips participants with the knowledge and skills needed to carry out an effective measurement system analysis.

Our MSA Training offers various advantages, including:

- Improved Measurement System Reliability: Learn to identify sources of measurement error, assess system performance, and take corrective action to ensure reliability.

- Enhanced Data Accuracy: Get insights into statistical techniques and tools to analyze and interpret measurement data accurately, reducing errors and variations.

- Making Informed Decisions: Take advantage of reliable measurement systems to make data-driven decisions, which leads to improved process control and quality outcomes.

- Identification of Improvement Opportunities: Find and address measurement system issues, contributing to continuous improvement efforts and higher operational efficiency.

- Compliance and Customer Satisfaction: Align measurement systems with quality standards, customer requirements, and regulatory compliance, reinforcing trust and loyalty.

Make the most of your quality control practices and choose the MSA – Measurement System Analysis Training from Swades QMS to get the best results!

Training Approach

Our Measurement System Analysis Training immerses participants in an interactive and engaging learning environment that promotes collaboration and active participation. Through group discussions, interactive exercises, and Q&A sessions, participants gain a comprehensive understanding of MSA concepts. To reinforce learning, the training also incorporates hands-on exercises and real-world case studies and examples to show how MSA can be effectively implemented in various industries and scenarios.

Additionally, our Measurement System Analysis Training follows industry best practices and relevant standards to ensure accuracy and consistency in measurement system analysis. By equipping participants with the knowledge and skills to analyze, interpret, and improve measurement systems within their organizations, our MSA Training helps them confidently apply MSA techniques and comply with quality requirements.

Training Content

I. Introduction to Measurement System Analysis (MSA)

- Importance of accurate and reliable measurement systems in quality control

- Overview of MSA and its role in assessing and improving measurement system performance

- Benefits of conducting MSA in various industries and applications

II. Basic Concepts of MSA – H3

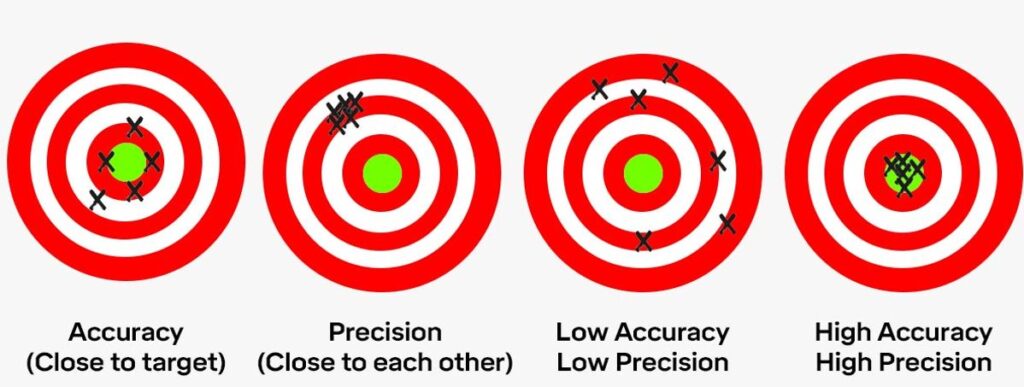

- Understanding variation and its impact on measurement data

- Components of a measurement system: equipment, operators, and procedures

- Sources of measurement error and their effects on data accuracy and reliability

III. Types of Measurement Systems

- Attribute and variable measurement systems

- Continuous and discrete measurement data

- Discussion of specific measurement systems relevant to participants’ industry or field

IV. MSA Framework and Plan

- Overview of the MSA framework and its key elements

- Steps for developing an MSA plan for a specific measurement system

- Considerations for selecting appropriate MSA techniques based on measurement data characteristics

V. Gage R&R Studies

- Introduction to Gage R&R studies and their purpose in MSA

- Conducting a Gage R&R study: design, data collection, and analysis

- Interpreting Gage R&R results and making decisions based on the study outcomes

VI. Measurement System Capability Analysis

- Evaluating measurement system capability using measurement variation and tolerance information

- Calculation and interpretation of measurement system capability indices (e.g., Cg, Cgk, Ppk)

- Identifying opportunities for improvement based on measurement system performance analysis

VII. MSA Techniques and Tools

- Introduction to different MSA techniques (e.g., ANOVA, Attribute Agreement Analysis)

- Use of control charts for monitoring and evaluating measurement system stability

- Other MSA tools and software available for data analysis and interpretation

VIII. MSA Case Studies and Practical Exercises

- Analyzing real-world MSA case studies from various industries

- Hands-on exercises for conducting Gage R&R studies and interpreting results

- Discussion and sharing of experiences related to MSA implementation challenges and solutions

IX. MSA Implementation and Best Practices

- Considerations for successful MSA implementation in organizations

- Strategies for ensuring ongoing measurement system performance monitoring and improvement

- Sharing of best practices and success stories from MSA implementation in different industries

Q&A and Wrap-Up

- Addressing participant questions and concerns

- Summary of key takeaways from the training program

- Closing remarks and next steps for participants to apply the acquired MSA knowledge

Who Should Attend

- Managers, Executives, Engineers and Other Staff

- Students or any Professionals requiring an overview of Measurement System Analysis